Imagine the jersey you’re wearing at a marathon sending real-time fitness data directly to your doctor. Think about your clothing regulating its own temperature depending on the weather outside. All of this may be possible now thanks to the emerging technology we call Smart Fabrics.

Smart Fabrics or E-Textiles (or electronic textiles or smart garments) – whatever you want to call them – is a technology that has been in development for decades and yet it continues to be described as an emerging technology. That’s because the technology that’s described as emerging is a technology that is still continuing to evolve. It doesn’t necessarily mean it’s brand new. This is the case for Smart Fabrics.

But before we get ahead of ourselves. Let’s explain what Smart Fabrics are and what constitutes a fabric as smart.

What are Smart Fabrics?

Simply put, Smart Fabrics refer to any textile that retains a digital component. It can be a battery, a chip, a sensor, or something similar. The technology is usually incorporated into the fabric through conductive fibers, multilayer 3D printing, or some other method. Whether it’s for pleasure, performance, or safety, these e-textiles are manufactured and designed to integrate digital components that offer the wearer or user greater functionality and higher value. The industries Smart Fabrics are used in can vary from health, public safety, corporate, lifestyle, etc.

History of Smart Fabrics

Like we stated earlier, smart fabrics are not new by any means despite their constant evolution. In fact, you can trace such technology all the way back to the 1600’s where gold conductive threads were woven into garments for a gleaming accent.

Nowadays, we use silver or nickel threads for conductivity, but the idea behind metallic threads has existed for centuries.

However, smart fabrics wouldn’t see much development until the early 1990s when MIT students started reaching smart apparel for military use. In 1996, the conductive fabric superstore, Less EMF, for EMF blocking purposes launched.

In 2000-2009, E-textile Lounge launched as a resource for e-textile crafting and development. In that same decade, Plug and Wear launched, which sold conductive materials for knitting and sewing.

In 2009, Forster Rohner launched the Climate Dress using their innovative embroidered techniques.

In 2011, MICA Fiber Department started to explore conductive thread and electronics, creating the Midi Puppet Glove. A year later, Drexel launched their Haute Tech Lab, which explored smart fabrics and additive manufacturing for textiles. In 2014, Dupont presented their stretchable, conductive ink at Printed Electronics 2014. That same year, Bebop Sensors launched wearable tech and textile circuits that were printed using Dupont’s conductive ink.

In 2015, Ralph Lauren and OMSignal teamed up for Polotech Shirt and ZSK embroidery revealed conductive thread and sequin LEDs that are compatible with their machines.

Current State of Smart Fabrics

And now in 2021, companies like Google and Levi’s are working together on a future smart denim jacket that uses Google’s Project Jacquard smart technology, which is a smart fabric sleeved denim jacket with built-in touch controls. The jacket also uses Bluetooth and conductive wire to communicate with a partner smartphone app.

Microsoft and Apple are applying for their own patents to develop smart fabric technology and integration. Recently, Apple filed one in order to integrate health monitoring technology into clothing. Similarly, Microsoft filed a patent for smart knitting technology that would be embedded into yarns for electrical functionality.

Smart textiles can now be programmed to monitor all sorts of things like biometrics and biofeedback, which can simultaneously measure physical attributes like a heart rate and send that information directly to the wearer’s doctor.

These types of application possibilities are endless in the healthcare industry, in particular.

Types of Smart Fabrics

Smart fabrics, as a whole, can be grouped into two board categories:

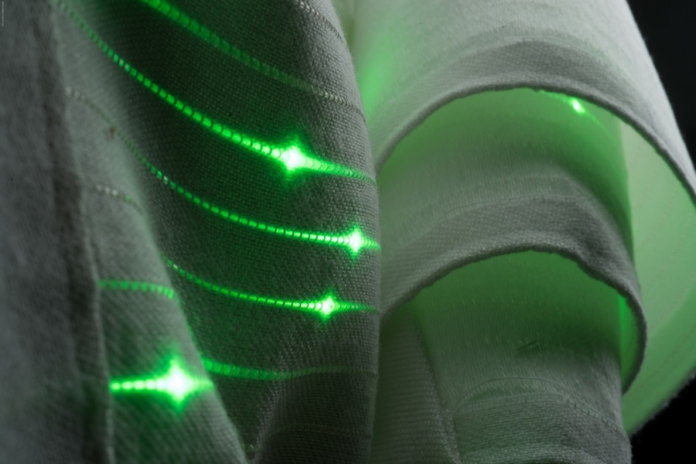

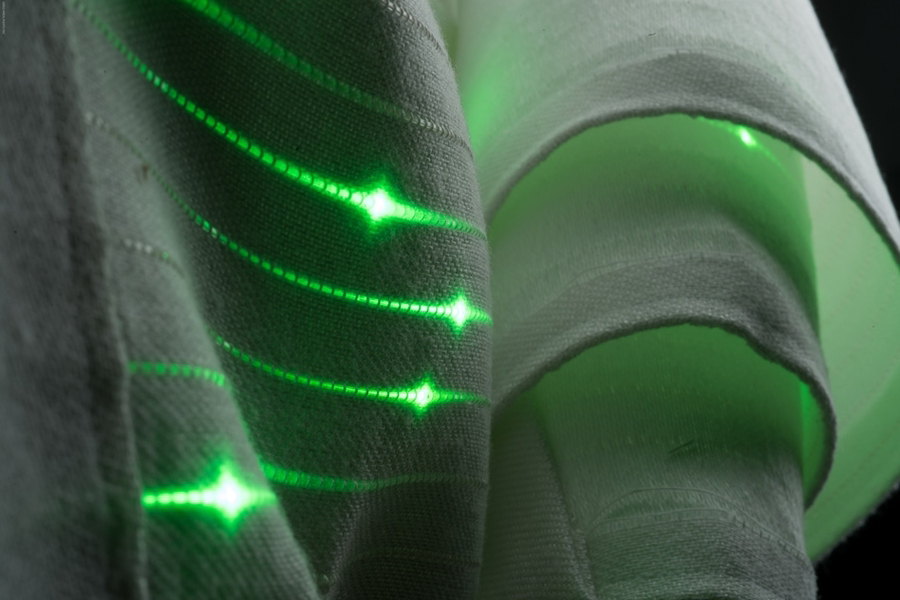

1) Aesthetic smart textiles, which is primarily for fashion, lifestyle, or design purposes. This can include sneakers that light up and fabrics that change color with body heat or any technology that adds a multi-sensorial experience through the use of lighting, sounds, colors, etc.

2) Performance smart textiles, which are fabrics that focus on improving performance by helping human functions like body temperature, perspiration, heart rate, and more. Some examples may include fabrics that regulate core body temperature or textiles that shield a wearer from radiation poisoning or other environmental hazards. But let’s break these down further into their core types.

Although there is no actual classification of smart textiles, they can still be divided up by their functionality into three types.

1) The first generation (passive smart textiles) – The first generation of textiles are able to perceive data about the conditions of the environment. Such type of textiles contains only sensors which include UV protective clothing, plasma-treated clothing or fabric with optical sensors.

2) The second generation (active smart textiles) – The second generation of smart textiles comprise both sensors and actuators. They can retain shape memory, uphold a chameleon effect, regulate temperature, resist water, heat fabric, and more.

3) The third generation (ultra-smart textiles) – This advanced type can not only sense disparate data types but also forecast and fix external conditions without preliminary tuning. Such kind of textiles works like the brain due to a built-in microcomputer. Some examples include spacesuits, I-wear, musical jackets, and so on.

Military Applications

Smart fabrics are quickly transforming uniforms (specifically military uniforms) into sources of data that can be transmitted to and from the wearer themselves.

Recently, M.I.T. developed a technology that can transform uniforms into wearable computers using smart clothing fibers. The Army can use the electronic textiles to power sensors that collect data on the wearer and their respective environment and transmit it back to headquarters.

The fibers can also warn the wearer of potential danger or hazards like chemical attacks. They can mark the wearer’s location for the rest of the team and bases of operations.

Thanks to a $302M endowment from the DOD, M.I.T. researchers for Soldier Nanotechnologies created polymer fiber prototypes that contain hundreds of tiny silicon microchips that can sustain a digital connection if and when electrified.

This type of technology can power even artificial intelligence applications as they can collect data that an algorithm could later interpret to detect changes in the user or surrounding environment.

Just as importantly, the fibers can track heart rates, breathing, muscle data, and more that could be used to warn headquarters of a possible health issue. All of which can be used to help the army make informed decisions regarding the health of their soldiers.