|

By CJ Ryce, Staff Writer,

and Paul Malham, President, of Fast Embroidery

Police, EMS and fire rescue staff, for example, rely on public recognition to do their job quickly and efficiently. It is important that embroidery on their uniforms retain its color and quality and is consistent and immediately recognizable. Although the importance of quality embroidery is not as urgent in most other situations, the care taken with embroidery on public service uniforms sets a valuable standard.

Company logos generally appear on the left chest and any personalization, such as an employees name, on the right. Design elements should be small enough to fit comfortably in the available space. This has been a particular issue on womens apparel.

Standard left chest placement on mens medium to extra large shirts is eight-inches down from the shoulder seam and four-inches over from center of the shirt (measuring from the center of the design).

For women, left chest design placement should be adjusted to six-inches down from the shoulder seam and placed at a point that falls midway between the center front of the garment and the armhole seam. Think of it as where a woman places her hand on her chest when she places it over her heart.

Left chest design placement on a womans shirt may also need to be reduced in size as much as 10-15% to display appropriately. It is advisable to test your design for placement by printing it out at the requested size and viewing it pinned to the appropriate location on the garment.

The maximum width for a left chest design on a shirt is approximately four-inches. However, less is usually better, even on mens shirts. Be aware that as a design is reduced in size, text size also is reduced and may become too small to be properly digitized.

The left front collar area presents a stylish opportunity to add initials, a unique design or a simple logo to a shirt. Private schools have begun to apply initials to uniforms in this way to provide identity when sweaters and vests can potentially conceal a left chest application.

Embroidery sewn along the hem of the left sleeve adds a creative touch as well as providing an attention-grabbing forum for a business message or slogan.

A tone-on-tone logo or stylized initials on a shirt cuff can provide another subtle, classy form of identity.

Uniforms traditionally come in sturdy blends of polyester and cotton twill (common for industrial and commercial work wear) and offer a good canvas for embroidery. A recent innovation for work wear is wickable fabrics, which have a high synthetic fabric content. Wickable fabrics originated in clothing designed for extreme sporting events, like mountain climbing, and have since progressed to shirts designed for work wear. For hotel staff, school uniforms or other softer uniform environments, silk, the newer micro fiber fabrics and a polyester/rayon that looks and drapes like silk can provide a comfortable, functional alternative.

The key is to select a quality fabric that will support the function and image a company or organization would like to present to the public. Thinner fabrics may cost less but do not maintain their fit and shape as well as a better-quality fabric. Along with stretchy materials, like jersey, they may require understitching in the embroidery process. Go for quality. Quality fabrics may cost a bit more but will last longer, provide a better canvas for the embroidery process and provide a polished, professional appearance that fosters trust.

With its vibrant color and high luster, the preferred choice of thread for embroidery destined to make an appearance in the classroom, boardroom, sales office or other soft setting is rayon. Rayon is the ideal choice for fabrics washed in cooler temperatures with color-safe bleach. Keep in mind that sports or commercial uniforms destined for hot water laundering and/or large amounts of chlorine bleach will need polyester thread with its strength and resistance to fading.

For industrial or commercial uniforms, the trend is moving away from the use of name tags. Embroidering directly to the fabric is fast becoming the standard. The result is a less clinical, more personalized and professional image.

If shirts that are to be embroidered are acquired offshore, however, keep in mind that pocket placements are sometimes angled incorrectly or offset to the left or right. Lining up a logo is difficult in such cases. We suggest ordering a shirt sample from an offshore vendor prior to placing your order. Hold off ordering a large quantity of shirts until you receive an actual sample. If you find yourself in a situation where shirts have been delivered with pockets misaligned or offset, find an embroiderer who will work with you to compensate for the misalignment by modifying the angle or placement of the embroidery.

Letter size is a major issue when embroidering on fabric. Tall skinny text and extremely small text do not sew out well on pique, jersey, terry cloth, corduroy and Polar Fleece. Text sewn out as a running stitch (in a single line) will, in fact, literally disappear beneath the knap of some loosely woven or plush fabrics. In such cases, a layer of under-stitching may need to be added or some of the design elements enlarged.

When applying small text to heavy or loosely woven fabric, a sans serif typeface, such as Ariel, or a simple, cursive font works best. A cursive font like Monotype Corsiva offers some latitude for imperfections in the sewout process because it is less likely to show misalignments than a block-type font. The key is to make certain that the lines of text have enough thickness to be satin stitched. The minimum line thickness for satin stitching is 1/32 of an inch.

On the other side of the coin, thinner fabrics, such as jersey, can make applying small text difficult due to its inability to hold its shape on the embroiderers hoop. In such cases, backing will probably be needed to maintain the integrity of the design. For fabrics that do not hold their shape well due to a stretchy or loose weave, text should be kept a minimum of 1/4 of an inch in height. You might also select a heavier, better-quality fabric, which may be more expensive but could save you money in the sewout process.

The following are general guidelines to gauge minimum text heights on commonly used fabrics:

Pique, Jersey, Terry cloth, Polar Fleece, Corduroyat least 1/4 inch

Twill, Microfleece, Denim, Most other fabricsat least 3/16 inch

NOTE: Re-designing a logo may be necessary to keep text a minimum of 3/16 inch or 1/4 inch in height.

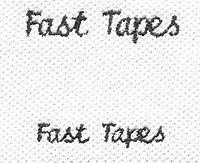

Text on pique, thick, plush fabrics or stretchy fabrics that do not hold their shape well should be no less than 1/4 inch in height. The image above illustrates the difference in sewout quality on pique fabric using a simple cursive text at 1/4 inch and 3/16 inch in height. Pique tends to push the needle around during the sewout process and can distort text characters and alignment.

When the protocol for business attire relaxed, the door opened for new and creative ways to embellish promotional business apparel. Take advantage of that opportunity by thinking outside the box with creative solutions to a companys identification challenges. In cooler temperatures where sweaters and vests are a mainstay during the winter months, you could suggest a coordinating shirt and sweater or vest combination. A stylish version of the company logo can be added to the left front collar of a dress shirt and a standard left chest version embroidered on the sweater or vest. This ensures a visual display of the corporate logo with or without the sweater or vest.

Embroidery plays an important part in the uniform apparel industry. Take the necessary time to determine the best choice of the key elements: fabric, thread and design placement. It will help you maintain a high level of quality and assure customer satisfaction.

|