The mounting threat of plastic pollution has led the researchers at the Massachusetts Institute of Technology to come up with an ingenious solution to recycle plastic bags and wraps into textiles.

According to reports, 380 million tons of plastic is produced globally every year, out of which 35.7 million tons is used by the US alone. While a plastic bag is used for approximately 12 minutes, it can take up to 500 years or more to decompose in a landfill. Thus, it’s no surprise why the dead weight of plastic is increasing at a staggering rate, putting the ecological balance of the planet at stake.

Besides plastic, cotton, a staple commodity in the textile industry, also poses an imminent threat to the ecosystem. The fluffy natural fiber alone consumes about 4% of the world’s pesticides in cultivation, which leads to the contamination of soil and groundwater.

Keeping in mind the adverse ecological outcomes caused by widespread plastic pollution and the use of pesticides in cotton cultivation, scientists at MIT are considering the possibility of developing sportswear, shoes, army uniforms, and even spacesuits by recycling plastic bags. If made possible, it would bring about a huge transformation in the fashion industry as apparel made out of recycled plastic would be extremely durable, dirt-resistant, and can be washed in just 10 minutes on a cold cycle.

“Once someone throws a plastic bag in the ocean, that’s a problem. Those bags could easily be recycled, and if you can make polyethylene into a sneaker or a hoodie, it would make economic sense to pick up these bags and recycle them,” says Dr. Svetlana Boriskina, a research scientist at MIT’s Department of Mechanical Engineering, in a statement.

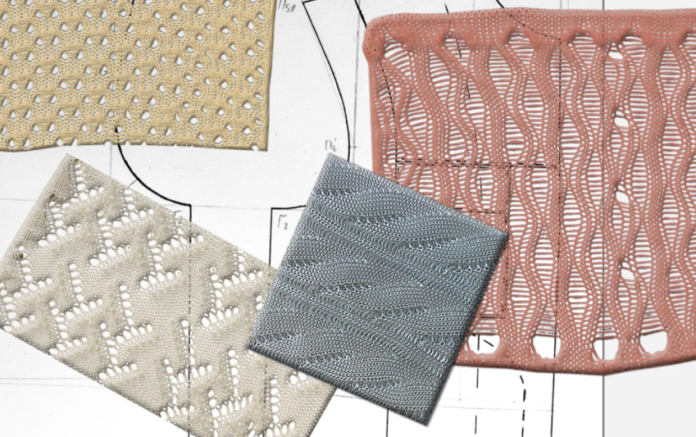

The engineers have found a way to spin polyethylene into fibers and yarn obtained from spaghetti strings and weaved in a way that it wicks away water and perspiration. The researched came up with the yarn by testing the wicking ability of cotton, nylon and polyester by dipping strips in water and measuring the time it took for the liquid to get absorbed.

It has been found that polyethylene did lose some of its wicking ability after repeated wetting, but the material can be rejuvenated with some friction and exposure to ultraviolet light. Dr. Boriskana also stated that polyethylene has a lower melting temperature and therefore costs less energy to produce.

“Synthesis of raw polyethylene releases less greenhouse gas and waste heat than synthesis of more conventional textile materials such as polyester or nylon. Polyethylene is difficult to get dirty, and could wash it on the cold cycle for 10 minutes, versus washing cotton on the hot cycle for an hour. Cotton also takes a lot of land, fertilizer, and water to grow, and is treated with harsh chemicals, which all produce a huge ecological footprint,” says Dr. Boriskina. “It doesn’t get dirty because nothing sticks to it. You could wash polyethyelene on the cold cycle for 10 minutes, versus washing cotton on the hot cycle for an hour.”

The research is supported in parts by the U.S Army Research Office, the Advanced Functional Fabrics of America Institute, MIT International Science and Technology Initiatives, the MIT Deshpande Center, and the MIT-Tecnológico de Monterrey Nanotechnology Program.