| By Jackie Rosselli |

What’s in a name? Well, that depends on who is answering the question. For industry veterans, HWC stands for Hamburger Woolen Company, Inc. The 74-year-old family-owned company began life selling fine uniform fabrics. In 1940, the uniform fabrics sold by Hamburger Woolen were 100 percent wool because synthetic fabrics hadn’t been invented yet. Therefore, the founder, Irving Hamburger called his new business Hamburger Woolen Company.

HWC is much more than that today, and indeed, that is the message the company wants to convey. Sure, HWC still stocks fabrics, and its inventory – no, that’s not a misprint because “inventory” is not a dirty word to HWC – is far reaching and ranges from wools to poly/wool blends to everything in between, many available with today’s performance-enhancing features. Hamburger Woolen continues to bring its expertise at world-wide sourcing to its customers. HWC is able to translate a customer’s special interests to find or create their fabric wishes.

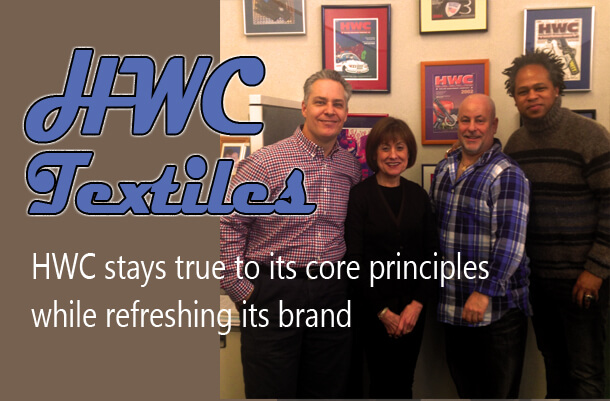

“We’re really Hamburger Textiles,” says longtime employee and General Manager Eric Gilman. “We sell so many different kinds of fabric that calling us ‘Hamburger Woolen Company’ is a misnomer!”

Lamont Reese, sales manager for the Public Safety division, reinforces this name revision. “We call the law enforcement and public safety equipment side of the business ‘HWC,’ not ‘Hamburger Woolen.’” The youthful Reese brings a different energy to HWC. He helped brainstorm the current logo that uses HWC as the name of the company. Hamburger Woolen Company, Inc., is written in smaller print under HWC. “We’re not shunning our history, but we are much more than a fabric company.”

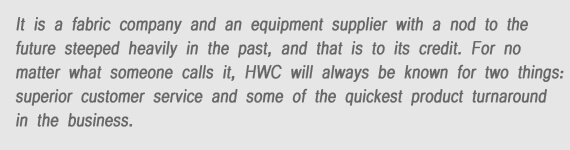

In truth, HWC is both. It is a fabric company and an equipment supplier with a nod to the future steeped heavily in the past, and that is to its credit. For no matter what someone calls it, HWC will always be known for two things: superior customer service and some of the quickest product turnaround in the business.

“We are a hands-on company that goes the extra mile for our customers,” says Gilman. “We spend a lot of time on the phone or corresponding with them by email. We answer whatever questions a customer may have. Our goal is to educate them so that they understand what they are ordering and keep them coming to us with more questions and hopefully more orders.”

And that’s not just talk. Over the years, COO Ilene Rosen has taken time with customers to develop a new and special program just for them. “We sit down with the customer, often face to face, to determine what they want,” begins Rosen. “Sometimes they don’t know the answer, so we ask questions. Do you want a poly/wool blend or 100 percent wool, a 100 percent polyester or a poly/ cotton blend? What about the weight? Did they want a twill or a plain weave? After the initial discussion, we go back to the appropriate mill to find out how to meet the customer’s needs and ultimately present them with a sample.”

They are also conscious of a customer’s budget constraints. Rosen says, “One customer wanted the benefit of wool and wool’s breathability feature without the cost, so we came up with Express Dry Finish, similar to a moisture-wicking finish. We applied this finish to a 100 percent poly fabric, thereby, saving the customer money but accomplishing their needs.”

HWC will also develop custom fabrics for customers, and then these fabrics become exclusive to that customer. The resulting fabric isn’t shown to anyone else in the industry until the customer stops using it, according to Rosen. “We helped develop a poly/wool fabric with a particular pattern using six colors of yarn. It took many, many months until the customer was completely satisfied with the new fabric.”

Why does HWC do this? Rosen says they do it so that the customers won’t have to. HWC is able to source a product and find exactly what a customer wants because they listen to their customers. “We’ve developed strong relationships with the mills we work with,” notes Rosen. “We’ve been around a long time. I know my business.”

Family-owned HWC was founded by Irving Hamburger on Jan. 1, 1940, at a time when there were no synthetics or polyester uniform fabrics. He saw that, while large manufacturers could purchase hundreds to thousands of yards, there was no way that small companies could manage to either afford or warehouse the huge quantities that were mandated by many mills of the era. So, he decided to become a distributor of these goods by buying full lots of goods. He warehoused them himself, cut them up and resold them to smaller manufacturers on an “on demand” basis.

Family-owned HWC was founded by Irving Hamburger on Jan. 1, 1940, at a time when there were no synthetics or polyester uniform fabrics. He saw that, while large manufacturers could purchase hundreds to thousands of yards, there was no way that small companies could manage to either afford or warehouse the huge quantities that were mandated by many mills of the era. So, he decided to become a distributor of these goods by buying full lots of goods. He warehoused them himself, cut them up and resold them to smaller manufacturers on an “on demand” basis.

After Hamburger’s untimely death in 1953, his sons Lloyd and Stuart Hamburger and his son-in-law Nathan Taffet took over the business. Together they expanded and grew the business tremendously.

In fact, Stuart Hamburger was the one responsible for starting up the HWC division in the early 1970s. He began with whistles, whistle accessories and handcuffs. The catalog, which is more than 90 pages today, started on just one page!

Rosen, who is Irving’s granddaughter and Lloyd’s daughter, continues the family ownership tradition today.

This history is important because some are under the mistaken impression that HWC is a jobber; it is not. Nor is it a mill.

“We are no different than many other companies selling fabric,” notes Gilman. “They don’t own their mills but they sell fabric, just like us. We are really wholesale distributors of fine uniform and career apparel fabrics”

HWC still counts on lessons learned in the past. “We still call the customer to chat; we don’t just call when there’s a problem,” says Gilman.

Reese adds, “You’d be surprised what you can start with a phone call,’’ noting that when customers call HWC, they get a live person, not an automated list of options.

Then there’s the staff. Most have been with HWC for decades. And while they may not all be related any longer, they still consider themselves family.

“We communicate and respect one another,” notes Gilman. “We are all treated like family. I have worked here for 30 years. That is a testament to this company.”

Rosen echoes that sentiment. “We are devoted to one another; one team with one goal.”

That goal is to provide a level of service unmatched by any in the business. HWC will cut one yard or 1,000 yards. It keeps inventory; lots of it. In fact, its inventory includes fabrics it no longer owns, what HWC calls its “best kept secret.” Rosen explains: “If a customer has purchased fabric and does not want to warehouse it themselves, we will provide the warehousing for them. We bill and hold that fabric and will cut it and ship it as instructed by the customer. We keep superb records for the customer and update them every month.”

HWC’s quick turnaround is legendary. Orders usually go out the same day, most within 24 hours. “What’s in our catalog is in stock,” notes Reese.

In all its years of business, HWC has never gone direct. This practice is more about ethos than business. “We cherish the customers we have and we don’t want to compete with them,” says Rosen.

Gilman notes some of the obstacles of the business model. “Growing the fabric side these days is not without challenges. It’s a challenge to find new manufacturers in the USA.”

And forget about the renewed interest in American-made products “We have a factory in Maine that manufactures many of our equipment items. We’ve found that many purchasing agents are not interested in these USA-made products. As everything seems to be about price, budget-conscience buyers do not buy these items,” Gilman adds.

Some time back, Rosen had the business certified as woman-owned, hoping the status would attract new customers. But the label has produced little reward; HWC has never won a bid or a contract based on its Women Owned Business certification. Plus the initial certification documents and astonishing amount of paperwork makes one wonder if the process is more time consuming than profitable.

New opportunities do exist, however, especially on the equipment side of the business. True to its past, HWC is the distributor of products sold by small and large manufacturers, and the reseller for dealers. This is largely because the company has no minimums and quicker turn times as compared to the manufacturers.

The HWC brand is another reason why HWC stands apart from other distributors. It has its own line of leather, web and nylon goods made in the USA, handcuffs, handcuff keys, whistles, plastic nightsticks and many more items.

The continuing success of HWC is due in large part to Will Davidson, the manager of the Law Enforcement and Public Safety Equipment Division. Having been with the company for more than 29 years, he is acutely aware of the industry trends and adjusts business accordingly.

The SHOT Show, too, has opened new doors. Reese says, “SHOT is an opportunity to see dealers all in one place, to show what we sell and make new connections.”

Naturally, HWC is online, with an active ecommerce site where customers can view and order from the catalog of products.

HWC is always on the hunt for new items to distribute, but it is cautious about what it pursues. “It has to be the right fit for our industry,” says Rosen.

Which brings up another point: in its 74-year history, HWC has seen companies come and go. HWC doesn’t just sell the uniform market; it is connected to it and, as such, is vested in its future.

“Look who’s still standing,” says Rosen to the naysayers. “Our employees are knowledgeable, and we are good at what we do. We’re not here to ruin the industry by cutting margins. I want my competitors to profit, just as I want to profit.”

A belief in people – whether it is staff, customers or a competitor – and the industry it represents is at the heart of HWC principles, and perhaps that is its greatest asset. “We’re still warm and comfortable but we have a definite nod to the future,” says Reese. “We listen. If you don’t, you become a dinosaur… extinct.”

Hamburger Woolen Company, Inc.

P.O. Box 796, 23 Denton Ave.

New Hyde Park, NY 11040

(866) 332-1899