Worker protection is of the utmost importance no matter what the field. But this is especially true in the area of public safety, where clothing and uniforms are not only paramount to worker safety but also the security of those they are called to assist. When the situation arises and these individuals are called into action, gear reliability should be a given, not a variable. This means not only having the highest quality uniforms and products but those that successfully combine performance with comfort and safety.

While this notion may seem elementary, take into consideration the many variable factors across the fire response, oil and gas industry. In the United States alone, there are a multitude of climates, environments and even daily conditions that are ever changing. This makes it imperative for providers of flame-resistant uniforms to constantly be on top of these changes and the increasing demands to have clothing and gear that suits the different conditions.

While this notion may seem elementary, take into consideration the many variable factors across the fire response, oil and gas industry. In the United States alone, there are a multitude of climates, environments and even daily conditions that are ever changing. This makes it imperative for providers of flame-resistant uniforms to constantly be on top of these changes and the increasing demands to have clothing and gear that suits the different conditions.

“We see continuing demand for FR clothing,” states Sandy Finkelstein, senior vice president and general manager of Walls Industries. “While historically our core focus has been with coveralls, customer preference has diversified into other programs including shirts, jeans and insulated FR clothing. We are now expanding our FR product offering to include other fabrics and products that cater to warmer climates that still keep the end user protected but provide more comfort.”

An example of this is the California Department of Forestry and Fire Protection (CAL FIRE), which serves and safeguards the people and protects the property and resources of California. Each year, CAL FIRE answers the call to more than 300,000 emergency incidents. In a state where the weather can change in the blink of an eye and treacherous conditions are in abundance, having top-notch uniforms and equipment is a requirement.

In these quick response jobs where the surroundings can change drastically on a daily basis and where every second counts, it’s imperative to have items – in particular, flame-resistant uniforms, boots and accessories – that can handle all of the elements. When working under pressure in hazardous conditions is often a daily task, it’s also necessary to have clothing that keeps workers cool and absorbs the surrounding elements, even when that might seem impossible. These items typically go unnoticed to bystanders, yet those who use these items rely on them immensely throughout their daily endeavors.

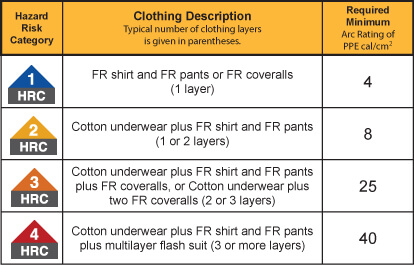

A common issue with flame-resistant clothing has been finding the happy medium between comfort and safety. This is especially true when considering the regulations that are put in place, specifically the National Fire Protection Association’s 2011 standard, NFPA 2112, which sets requirements on Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire. The NFPA has identified four FR hazardous risk category levels, which are numbered by severity from one to four (see chart below).

“Hazard Risk Category” is the level of arc flash protection clothing that FR workers must wear to protect themselves against a minimum level of incident energy measured in calories per square centimeter. Essentially the NFPA has set levels of energy different electrical equipment can deliver if it fails and causes an electrical arc. The resulting explosion can deliver a certain amount of heat to a certain distance. Each HRC level is rated at a certain amount of flame resistance needed to protect a human from that sudden delivery of energy. A zero rating means no arc threat is present and thus no FR clothing is required.

The NFPA 2112 provided minimum performance criteria and sets clear guidelines for minimum design and performance certification requirements and test methods for FR garments that will be used in areas at risk from flash fires. Potential areas include those where flammable gases or vapors or combustible dusts might be present. For a garment to pass NFPA 2112 testing, it must exhibit 50 percent or less total predicted body burn using a standardized burn injury model. Meeting these standards while maintaining user comfort can be a trying task, so finding the right balance goes a long way in creating the best possible products.

“Lack of comfort can be a barrier to compliance with safety regulations, and typically FR has been seen as uncomfortable and hot,” says Carolyn Kidd, marketing manager at Drifire. “Our garments are inherently flame resistant but incorporate performance technologies that make them antimicrobial to resist odor and include moisture management to dry fast and regulate body temperature. These design details always keep the end user in mind and allow them to avoid the tradeoff between comfort and compliance.”

Finklestein says, “When the new NFPA 2112 standard was adopted last year, we had all of our core products tested at UL to meet these requirements. In addition, we are now seeing a groundswell in demand from all of the personnel – electricians, independent contractors, truck drivers, etc. – that provide field support to these North American shale plays (rural areas). These are coming in from multiple channels, including safety suppliers, industrial laundries and retail. Our outlook for this category of business is very positive, reflecting increasing demand year-over-year for the foreseeable future.”

With these changing regulations and compliances, along with the importance of maintaining user comfort, it remains essential to have a continuous emphasis on safety, both for the worker and those around him. Firefighters and other individuals in the public safety field are often looked at as invincible. And while this is not necessarily a bad way for them to be portrayed, it’s still important to point out the risks and dangers when a fire-related predicament arises.

Bulwark Protective Apparel, the flame-resistant workwear brand of VF Imagewear, has taken a dynamic approach to this with the release of 451 Degrees, a stunning and thought-provoking film that focuses attention on one simple fact: people are not fireproof.

A large manufacturer of flame-resistant apparel for industrial workers, Bulwark wanted to focus attention on the relationship between people and fire, specifically individuals working in hazardous environments such as those in the oil and gas industry, electric utility workers and commercial electricians.

“We’re seeking to engage our customers with an artful film that elevates the discussion about fire safety in the industrial workplace,” says David Crace, Bulwark VP of marketing. “It is a compelling reminder that safety matters, because lives are at stake.”

This film, which premiered in June at the Wells Fargo Theater in Denver, opens with a dramatic view of an industrial worksite sculpted completely from paper. This 3-D sculpture imagines a facility with oil derricks, exhaust manifolds, electrical switches and piping systems and includes paper people at work throughout the site. As the camera explores the landscape, a small fire ignites, quickly spreading into a dramatic, all-consuming blaze. As the entire sculpture turns to ash, the simple phrase “Because people aren’t fireproof!” appears onscreen.

“451 Degrees will surprise many industry observers,” says Stan Jewell, Bulwark general manager. “Our customers are engaged in serious, sometimes dangerous work. We want them to know that we understand the risks inherent in their work and that Bulwark is committed to developing innovative products and services that increase safety and reduce risk.”

From its inception, Bulwark envisioned the project as one with greater appeal, not only to safety engineers and target industries but to people in all walks of life. Initial audience reaction has proven that the message strikes the intended chord, reinforcing that life is fragile and, like paper, people can be destroyed in moments.

“For Bulwark, safety is a shared and sacred responsibility,” says Jewell. “Safety is the driving force for everything we do; it’s what makes Bulwark a leader in the FR apparel industry and guides our innovation, products and service offerings.”

There are also a number of additional items worn by FR professionals, including logos, nametags, flags or other items used to identify an organization or end-user company. Each product type must be individually tested for flame and heat resistance.

“The garment companies consider logos as a value-added product,” says Randi Blumenthal-Joseph, president of Penn Emblem. “Thus, we meet anything that our customer needs, and we always try to exceed their expectation.”

In addition to custom-embroidered emblems, there are also special content emblems that can be used for embellishing uniforms or adding corporate identity to garments. However, while they perform that task, they also provide added safety, protection and security to the uniform wearer when working in hazardous or controlled environments.

Embroidered flame-retardant emblems are manufactured through the same techniques as custom-embroidered emblems. But instead of using the standard 100 percent polyester base materials, Penn Emblem uses flame-retardant fabrics.

“These emblems are manufactured with a myriad of materials,” says Blumenthal-Joseph. “When people are working in flame resistant, controlled environments, these materials provide that extra measure of safety.”

The FR clothing market remains steady for electric utilities as well. According to Chris Nowacki, business development manager at TecGen Select, facilities that employ workers exposed to combustible dust hazards will be a rapidly growing market for FR clothing dealers in the years to come. “It seems these days that end users are much more educated about FR clothing options compared to 10 or 15 years ago and are now seeking newer fabric technology to maximize comfort and protection for FR wearers,” he says. “We believe that FR clothing dealers that stay abreast of new technology and ever-changing standards will experience a great deal of success in this growing apparel market.”

The flame-resistant uniform industry can often be a trying business with the constant demand for items that best combine comfort and safety along with the ongoing changes to uniform regulations. For an organization to be successful, it must have its head on a swivel, always ready for the next steps in product innovation and improvement. Those that follow this model will no doubt be successful in providing top-notch items to individuals who protect the well-being of those around them on a daily basis.