The Uniform Genome

The human genome is the entirety of our hereditary information, and genetic engineering is the manipulation of the DNA that forms our genome. Genetic engineering has become a major force in agriculture and medicine, yielding spectacular results such as drought-resistant crops and life-saving vaccines, to name just a few.

The genome of uniform, footwear and gear retailers consists of catalogs and websites which hold the branding, product information and pricing DNA of manufacturers. A re-engineering of uniform industry DNA is underway and promises to yield spectacular results such the ability for manufacturers to automatically update thousands of retailer web pages and provide real-time analytics of sales activity, among other essential tools. This re-engineering will drive innovators in the uniform industry into a new era of prosperity, a period we call Uniform Industry 4.0.

Industry Road Map

There was a time in the pages of this magazine where companies advertised CMT services. Every garment required you to “cut, make and trim” it. The garment was truly made to measure, which is where the name of this 83-year-old magazine comes from. Let’s call this Uniform Industry 1.0.

Then came the age of mass production, a post-World War II bonanza where large manufacturers filled ever-larger warehouses with inventory. Retailers were sent scores of printed catalogs every year. Everyone had office filing cabinets full of them (many of us still do). Retailers received 50 catalogs from 50 different companies and eagerly passed them out to their end-user customers. We can say this was Uniform Industry 2.0, and we know that some people in our industry still live in this era.

By the turn of the millennium, Uniform Industry 3.0 allowed retailers to take the scores of catalogs they received from manufacturers and place them on a website where customers could access them from anywhere at any time. Online catalogs represented a giant leap forward in terms of easy access by customers but not a huge advancement in the labor-intensive process of maintaining catalog information. Most people in our industry are using Uniform Industry 3.0 technologies.

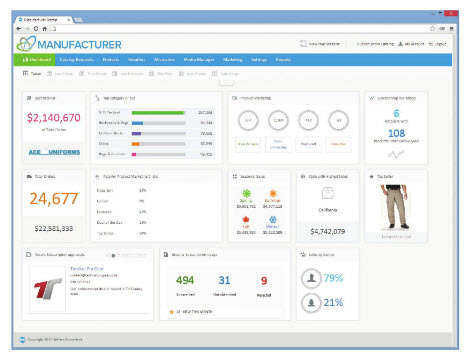

What we are approaching now on the technology roadmap is Uniform Industry 4.0. What does Uniform Industry 4.0 look like? In a word, efficient. In this new era, the internet and smartphones bring all trading partners together in a seamless flow of manufacturing, selling, fulfillment and reporting. The ability for a manufacturer to update their “catalog” goes from an annual ritual to part of a daily lifestyle. In turn, the retailer’s ability to display that updated product information goes from a labor-intensive activity to instant changes reflected on their website, in their back office computers and distributed to their sales team. In just the next few years, retailers won’t even need to update their catalogs, as web pages are automatically sent from manufacturers. Manufacturers, dealers and retailers won’t need to keep spreadsheets, as sales data and analysis automatically flows back from the analytics engine integrated into the uniform ecommerce platform they share.

What we are approaching now on the technology roadmap is Uniform Industry 4.0. What does Uniform Industry 4.0 look like? In a word, efficient. In this new era, the internet and smartphones bring all trading partners together in a seamless flow of manufacturing, selling, fulfillment and reporting. The ability for a manufacturer to update their “catalog” goes from an annual ritual to part of a daily lifestyle. In turn, the retailer’s ability to display that updated product information goes from a labor-intensive activity to instant changes reflected on their website, in their back office computers and distributed to their sales team. In just the next few years, retailers won’t even need to update their catalogs, as web pages are automatically sent from manufacturers. Manufacturers, dealers and retailers won’t need to keep spreadsheets, as sales data and analysis automatically flows back from the analytics engine integrated into the uniform ecommerce platform they share.

Efficient Use of Brand and Customer

Data = Profitable Growth

UniformMarket has been building uniform ecommerce infrastructure for several years, and we see our customers benefitting from our internet-based data and order flow ecosystem every day. It is especially clear that an efficient ecommerce system enables manufacturers to wring profitable growth out of two core assets: brand and customer data. UniformMarket is now set to drive efficiency and profitability to new heights by providing automated syndication of brand and catalog information, as well as automated collection and analysis of customer data.

Syndicating Brand and Catalog Info

Marketing and brand experts spend enormous amounts of time creating product, category, pricing and advertising messages that are designed to engage users at each point of the purchase cycle. In a perfect world, shoppers would experience a consistent and compelling brand message across dealer and retail web sites that present the brand. Not only would shoppers see the striking visual appeal that defines the brand, but they would also have access to the latest merchandising, pricing and product content.

However in our imperfect world, most shoppers do not even see the beautifully crafted manufacturer websites. They instead look for product information at local retailers in communities where they live and work or on the internet.

So the burden is placed on manufacturers to somehow syndicate their messages in a timely fashion. With existing uniform industry technology, this task is incredibly inefficient because getting new information into retailers is difficult and slow. Some manufacturers are still mailing a printed catalog from a 2.0 world. Some still rely on a sales person to call on retailers and hand deliver materials. Others shovel content with email messages.

Unfortunately, getting information to retailers does not guarantee it will be used the way a manufacturer intended, if at all. Many retailers simply do not have the technical or marketing skills to support frequent updates from multiple manufacturers. And for retailers that do have the expertise, web updates are expensive because they typically require time from owners and hired web professionals.

Unfortunately, getting information to retailers does not guarantee it will be used the way a manufacturer intended, if at all. Many retailers simply do not have the technical or marketing skills to support frequent updates from multiple manufacturers. And for retailers that do have the expertise, web updates are expensive because they typically require time from owners and hired web professionals.

The cumulative impact of inconsistent, outdated and/or inaccurate product information eventually leads to loss of brand value, competitiveness, sales and profitability for both the manufacturer and the retailers selling the products.

All this leads us to Uniform Industry 4.0. In this era, profitable growth will be achieved by manufacturers who streamline the process of updating thousands of websites using automated merchandising, pricing and product content syndication tools. The future is content syndication with manufacturers proactively assisting retailers down to the product page and site search level.

Collecting and Analyzing Customer Data

Manufacturers, dealers and retailers covet data about the buying behavior of customers. But manufacturers can be multiple dealer hops away from their retailers, insulating the manufacturers from consumer search and point-of-sale data. Dealers are only one hop away from retailers, but most retailers don’t possess the technology needed to upload good data.

This is why one of the most exciting capabilities built into ecommerce platforms in the Uniform Industry 4.0 era is automated data collection and analysis. Manufacturers, dealers and retailers who share a common platform will receive a continuous flow of fresh data about consumer demographics, navigation and sales history. From that data, the analytics engine built into a Uniform Industry 4.0 ecommerce platform will generate detailed reports and analyze the data for specific events and trends.

The Future is Now

The opportunity to increase the efficiency and profitability by plugging in to an advanced ecommerce platform is here today. Wherever you are in the industry road map, contact UniformMarket through uniformmarket.com about a demonstration of SellersCommerce, the uniform, footwear and gear market’s first 4.0 ecommerce platform.