|

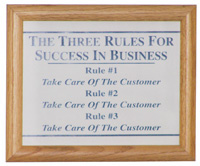

By Susan Derby On the surface, the sock industry may not seem like it has changed much in 30 years All it takes is one conversation with someone on the inside, though, and it’s obvious that huge shifts have occurred in styles, yarns, fabric technology and international trade. These shifts have had lasting ripple effects that could easily have sunk entire companies, yet Pro Feet Inc. has not only survived in its niche market, it has thrived with near-constant growth. Pro Feet can attribute its lasting success to many different factors. One is an owner with drive and passion. Russell Wilson founded the manufacturer in 1979 and is still owner and CEO. He began in the shoe business, working his way up to president of his division, until a headhunter asked him to visit a hosiery company that was looking for someone to run its day-to-day operations. He ended up taking the job and stayed there about nine years until he ultimately realized he would never be able to own the company outright. An entrepreneur at heart, Wilson then took financial stakes in a few hosiery mills in North Carolina. He even began a business with a friend, but that fell through when the two proved to be better friends than business partners. In 1979, he pulled out of all his other business obligations to start his own hosiery company, Volunteer Hosiery, in Burlington, N.C. That company changed its name to Pro Feet Inc. in 1983 when the University of Tennessee, whose mascot is the Volunteers, bought the rights to the original name. In the beginning, Pro Feet produced plain white socks and sold them through local retailers. Wilson quickly saw that he needed something to set his company apart from his competition, and he dove into filling the high demand of the uniform, military and sports footwear markets. That’s another of the factors to which Pro Feet attributes its success: listening and responding to customer input. “That’s one of the strengths of Pro Feet; we’re really willing to listen and willing to change,” says Callum Brown, vice president of operations. “It’s from customer feedback and listening to our sales people and the market that we decided to move into the team business. That was about 15 or 20 years ago, and then the uniform side has evolved. If there’s a need out there, we’re always looking at if we can fulfill it.” Now the manufacturer boasts 3,500 SKUs, including a small line of cheerleading apparel added at the request of its customers. In addition to the standard socks and hosiery, Pro Feet also offers custom orders. In batches as small as two dozen pair, Pro Feet will add custom colors, striping, lettering and logos to any style and silhouette it makes. The custom orders are popular with school athletic teams, but the company has also done custom designs for UPS, Coca-Cola and other companies. Lead time on custom orders is just four to six weeks, whereas most other items are available to ship from the warehouse the same day or within 24 hours. Brown says, “We carry everything on hand, especially on the sporting goods side. If someone places their order on Monday and they have a football game on Friday night, there just isn’t time to manufacture it and still get it to them on time. It’s a full-time job trying to maintain that ability. It’s critical in our industry that we have product available when customers need it, and I think we do a great job at that.” Pro Feet has been able to balance the convenience of domestic manufacturing with the economics of offshore production. Brown says the company likes keeping as much production here in the States as possible and that domestic production allows the company to provide uniforms to clients like the U.S. Postal Service, which requires all uniform components to be made in the USA. While most of the uniform socks are made in this country, the team sports side of the manufacturing is based in Asia. Pro Feet was forced to follow suit after many of its competitors moved offshore and could offer lower prices. But, as Brown points out, all of its best-selling socks for each the postal, public safety and athletic lines are made in the United States. He says the company is proud of supporting jobs here by maintaining domestic manufacturing capability. The downside of the industry-wide shift to offshore production is that it’s harder than ever to source the raw materials that go into hosiery production, and lead times have stretched much longer. It’s also gotten more difficult to find the skilled workers needed to knit the socks. Pro Feet Inc. employs about 50 sales representatives across the country, about 16 of which are focused on the uniform industry. Another 15 people staff the company’s 30,000-square-foot headquarters in administration, marketing, and distribution divisions. Among the staff is Russell Wilson’s own son, Taylor, who is the vice president of sales for the company. “Russell will tell you he wants to retire, but I think he just loves this company too much to really want to,” Brown says. “I think he’s energized by the challenges. I think it’s good for him to be around here, and it’s good for us too.” Russell provides a link to the company’s past, but that doesn’t mean he’s stuck in his ways. Instead, his philosophy of “Take care of the customer, take care of the customer, take care of the customer” is adhered to by all employees. A human being answers the phone, and that person is friendly and helpful. Sales reps are empowered to offer customization that is done quickly and accurately. Feedback from the distributors and end-users is listened to closely and brought into high-level reviews of all products. Pro Feet is also committed to innovation. It is using the latest in moisture-wicking materials and weaves to create sought-after new product lines and reach new customers. The company even has a line of footwear knitted with Cocona yarns, made from coconut shells. X-Static socks incorporate silver threads in the yarn that helps regulate temperature and kills the bacteria that causes odors. “We’re in an old industry, certainly,” says Brown, “but we’re competitively priced, we have a quality product, and we offer a one-year guarantee on any of our products. We try to be innovative and not try to do what we’ve always done with the same products.” Some customers have been with Pro Feet for 20 years. With more than 3,000 clients, Pro Feet is actively recruiting more customers. To help spread the brand, the company relies on its dealer network. It doesn’t sell directly to end users, a philosophy it has had since the beginning. Instead, sales reps and trade shows are the main networks it uses to attract new customers. “On the uniform side, we’ve been very involved with NAUMD. It’s very important to be able to get to our customers, to get that direct communication with them,” Brown says. Both Russell and Taylor Wilson have served or are serving terms on the Board of Directors of NAUMD. Brown says, “We’re big proponents of them.” In addition to trade shows, a website, launched around 1999 and updated regularly, helps provide more information on every sock Pro Feet offers. Potential customers can scan the site for full information on its postal, police, fire, public safety, sports and military hosiery, but they will need to use the handy “Locate a Retailer” tool to actually buy anything. Brown says the site has helped spread information about the manufacturer and its offerings without jeopardizing the solid dealer network the company has created. The manufacturer’s next goal is to gain a stronger foothold in the public safety uniform segment. Pro Feet has been developing socks tailored to the needs of police, security officers and firefighters. The product line and display rack were promoted at the latest NAUMD show. Pro Feet is passionate about its community involvement. It is a Gold Sponsor of the United Way, and contributes service and financial support to local colleges, universities, the Boys and Girls Club, and YMCA. For this company, being long-time residents in Burlington means giving what it can to help others. It’s able to do so because of the success it has enjoyed for 30 years. “Pretty much since the company was founded, we’ve had double-digit growth up until just a few years ago. It’s tapered off a bit just because it’s hard to continually grow at that pace,” Brown says. “We’re lucky we’ve been able to continue to grow.” Brown admits that 2009 might be a slightly different story. The economy has shaved profit margins to the point that the company is facing a possible down year, but only slightly. As other hosiery manufacturers are going out of business, Pro Feet has been able to pick up those customers and accounts. It’s just another one of those factors that has helped Pro Feet Inc. maintain its tradition of meeting the quality and performance demands of its customers. For 30 years, Pro Feet has been taking all the right steps in the hosiery manufacturing market. It’s been on solid ground from the beginning, and the goal is another 30 successful years of growth. After all, while styles and yarns have changed, one thing hasn’t everyone still wears socks every day. Pro Feet Inc.

|

|

| Above story first appeared in MADE TO MEASURE Magazine, Fall & Winter 2009 issue. All rights reserved. Photos appear by special permission. | |

| Halper Publishing Company 633 Skokie Blvd, #490 Northbrook, IL 60062 (877) 415-3300 Fax (224) 406-8850 [email protected] |

|