|

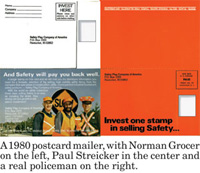

By Paul Streicher Norm Bernson, president of Safety Flag Company of America, leans forward across a cluttered desk. American manufacturing faces tough competition, but we are no way dead. The problem is that we have incredible tools in our back pocket, but we just dont know that they are there. Bernson thinks a lot about American manufacturing and its future. He is proud that he can compete against imports. It is possible in safety apparel and safety products, he says, because material, not labor, is the major cost, and he has been able to reduce materials costs and retain material quality by constant negotiation with suppliers. For more than 50 years, Safety Flag has been manufacturing fluorescent safety vests and flags. It makes fluorescent and reflective vests, flags and apparel, as well as banner tape, handheld traffic signs, traffic cones, barrier markers, roll-up signs, patrol belts and a host of accessories. Safety Flag serves many customers with special requirements, and this, too, is an advantage, he notes. Safety Flag serves police departments that want their barricade tape to read Smithfield Police, contractors who need extra-large reflective vests, and truckers who want banners saying, OVERSIZE LOAD instead of WIDE LOAD. An importer has to be rigid in what he sells, Bernson says. He cant do specials like adding pockets, zippers or velcro closures. He explains, If a rescue company wants to place a smaller order with specific reflective stripes, we can do it while the importers cant, and because the labor is not excessive, the price remains competitive. And were fast, he adds. We can make special sizes without waiting for a container to come in. He sits in a small, crowded office with notes and mementos pinned all over the walls. The door is open so he can call out to David Radler, his vice president and alter ego, whose desk is just outside and who has been with Safety Flag longer than anyone can remember, and to Mercedes Saint Clair, his smiling office manager, who is never handling less than three things at a time. Only a phone call away from the customer, Bernson remarks that Safety Flag is already streamlined, because we speak the same languages as our customers English, Spanish and Portuguese. That helps us to make fewer mistakes. We also make fewer mistakes because sales and management are right next to manufacturing. We dont have to go through translators or layers of bureaucracy to tell the sewing machine operator to make the windsock diameter wider. The only place an importer has an advantage is when you are ordering tens of thousands of exactly the same thing. Even then you have to hope there is nothing wrong. You can get a container of mistakes. Bernson also thinks hard about American quality. As Americans, we dont realize that the term American quality means a lot in the rest of the world. Whether they like us or hate us, the rest of the world knows that we have high standards, and they respect the quality that we take for granted. And when you are working with 3M Scotchlite, you know you are working with the highest of the high quality. With imports, quality is always a question. We assume quality, while they are always weighing how much is necessary. They will cut the quality in order to cut the price every time. If there is a problem in this country, it is that as Americans we assume quality. Price is more important than patriotism, and the customer, thinking that it is all alike, goes for the cheaper product. We are lucky that at Safety Flag we can keep the prices pretty low. In the future, as products get more sophisticated and require more labor, price competition will be more difficult. We will simply have to innovate faster than they can keep up. It wont be easy. How else are things changing in American manufacturing? For us, the business is changing because the government is continually adding minimum specifications for safety products. For example, there are now new specs for fluorescent vests. Right now the specs are voluntary, but eventually they will be mandatory with minimum amounts of reflectivity and fluorescent visibility for highway use. The industry is also changing because of the nature of American society. We are, frankly, litigious. As new technology develops, anyone buying vests for employees contractors, utilities, anybody who does not use the best vests available may be sued in the event of an accident. Right now, I would never advise anybody to buy anything but a vest made from first-quality materials such as 3M. The flag market holds the same dangers. Why use a faded flag, or an orange flag that isnt fluorescent? You are saving a dollar and opening yourself up to a negligence claim that could bankrupt your company and maybe you, too. Global awareness is changing the American market, too. In Spain and Italy it is mandatory that every car have at least one vest in it because of the possibility of a breakdown. There are U.S. congressmen who know this, and a similar law may appear one day in the United States. It wont happen this year, but nobody knows what will happen in the future. I earlier mentioned WIDE LOAD and OVERSIZE LOAD banners. We now have these in reflective material. This is great for truckers because it allows extra driving hours. It is a technological breakthrough that makes sense for their business. Looked at negatively, if you are driving a truck with a wide load and dont have a reflective banner, you are either restricting your hours or opening yourself up for potential problems, even without a law yet on the books requiring reflective banners. This kind of change is nothing new to us. When I first bought Safety Flag, CAUTION tape was new. Now it is a commodity. In 51 years, the Safety Flag Company of America has changed. Through hard work, attention to detail and dedication to quality, Weiss and the two Normans have developed a solid company built on customer service, honesty and hard work. For the last 10 years, even with a sometimes slow economy, it has grown an average of 5% per year. What is ahead? The company would like to make more acquisitions. Although it has 2,000 distributors, mostly American, it would like to add more. It would particularly like more distributors who sell overseas for, as the economy becomes more global, Safety Flag continues to compete. In fact, this year Safety Flag shipped 3,000 vests to an American company in Iraq , screen printed in Arabic. Dont ask me what it said, said Norm. Its all Greek to me. Paul Streicker is founder and president of Streicker & Company Inc., Safety Flags advertising agency since 1979. |

|

|

| Above story first appeared in MADE TO MEASURE Magazine, Fall & Winter 2004 issue. All rights reserved. Photos appear by special permission. | ||

| Halper Publishing Company 633 Skokie Blvd, #490 Northbrook, IL 60062 (847) 780-2900 Fax (224) 406-8850 [email protected] |

||