|

By Rick Levine The high-visibility safety apparel category, as a segment of the larger uniform industry, is healthy and expected to see steady growth for many years. There are two major driving forces affecting the market. One is the widespread recognition of the occupational hazards often associated with low visibility. The other is a significant industry and regulatory focus on traffic safety issues. Numerous private-sector studies and government reports, all of which support anecdotal experiences reported by industry members, have dramatically increased the acceptance of the direct relationship between visibility and worker safety. Employers and responsible parties are beginning to recognize that they must do everything in their power to make sure a worker is in fact visible on the job. This is partly due to a lively level of litigation and liability issues. The absurd upside to that fear of being sued is greater demand for high-visibility products. A little prevention on their part not only saves workers but also dollars. Another factor offering even more expansion of the high-visibility apparel segment is the increased availability of multiple-protection fabrics. These enhanced technical capabilities throughout the supply chain have offered uniform apparel manufacturers the ability to combine water, fire and chemical retardant/resistant features with both functional and visibility elements. End users are reaping the benefits of a single garment with multiple protections. Changing Trends in Applications Uniform manufacturer Fechheimer recently launched its Pro Series line for the market. Were continually seeking to develop the next generation uniform across all of our product lines. The new 207 standard and our partnership with Head Lites and 3M turned out to be perfect timing, says Fechheimer Vice President Fred Heldman. The 207 standard regulates high-visibility vests for public safety officials. It was created and is regulated jointly by the American National Standards Institute (ANSI) and International Safety Equipment Association (ISEA). Those agencies also set the ANSI/ISEA 107-2004 guidelines that apply to all forms of high-visibility garments. Heldman says, The Pro Series is about people, not vests, and it was clear in listening to our customers that public safety officers wanted products better aligned with their unique occupations. These are performance products, tactical in design, that allow police officers, firefighters and first responders to do their jobs safely, yet clearly identify them as public safety professionals. Other interesting style shifts include the increased use of high-visibility colors in corporate uniform designs and the use of multiple reflective formats. These variations on the traditional high-visibility colors and garment construction help to enhance a corporate brand and increase visibility in the process. Examples of this include the increased demand for custom finishing features, logos and graphics created from high-visibility transfer films and graphic transfers. Gary Pearson, marketing manager for 3M Companys Visibility and Insulation Solutions business, says, Innovative materials are being fashioned into an expanded variety of worker garments including short- or long-sleeve shirts, shorts, gloves, headgear, jackets and parkas that provide enhanced visibility in low-light conditions as well as maximize comfort, even after frequent launderings. These options make it easier than ever to move beyond the vest and select the right garments for the job. All this has translated into an increased presence of high-visibility work wear available as a variety of garments. Industry experts like to point out that the ANSI/ISEA 107-2004 standards are an apparel standard, not just a mandate for the wear of vests. In apparel catalogs, the now ubiquitous safety vest has been joined by everything from casual clothing such as T-shirts and sweatshirts to outerwear such as jackets and rain suits. The motivations for these shifts have a statistical basis. An ISEA study indicates that safety vests are not worn on the job up to 25 percent of the time, even when they are required. The reasons cited by workers for non-compliance are job performance interference, lack of enforcement, forgetfulness, soiled or torn vests or apparel, and lack of style or comfort. The uniform industry has been able to step to the plate and help solve the last two of those excuses. Escalating Legislation Will Drive Market ANSI is a private not-for-profit organization that oversees the development of voluntary consensus standards for products, services, processes, systems and personnel in the United States. ANSI accredits standards that are developed by representatives of standards-developing organizations, government agencies, consumer groups, companies and others. These standards ensure that the characteristics and performance of products are consistent, that people use the same definitions and terms, and that products are tested the same way. In conjunction with ANSI, the ISEA published the American National Standard for High-Visibility Safety Apparel and Headwear, and that standard now known as ANSI/ISEA 107-2004 became widely accepted as the benchmark to follow. To add some teeth to the standard, the Federal Highway Administration (FHWA) ordered compliance in the form of federal regulation Pursuant to Section 1402 of the Safe, Accountable, Flexible, Efficient Transportation Equity Act: A Legacy for Users (SAFETEA-LU). The bill is called CFR Part 634: Worker Visibility and mandates that by Nov. 24, 2008, all workers within the right-of-way of a federal-aid highway who are exposed to traffic or construction equipment within the work area shall wear high-visibility apparel that meets the Performance Class 2 or 3 requirements of the ANSI/ISEA 107-2004. The definition of workers, according to the bill, means people on foot whose duties place them within the right-of-way of a Federal-aid highway, such as: Highway construction and maintenance forces, survey crews, utility crews The minimum garment class requirement under the federal rule will be Class 2. While the rule does not encompass ANSI 207, it has been stated that the FHWA might consider revising this rule once this standard goes into effect. The government is responding in part to the Census of Fatal Occupational Injuries, Bureau of Labor Statistics which stated that struck-by-vehicle accidents accounted for 336 fatalities across all industries in 2005. In addition, there were 40,000 injuries in work zones. According to the General Estimate System, National Highway Traffic Safety Administration, road workers are in fact eight times more likely to be injured than other industry workers. But, road workers are not the only ones at risk. In 2005, fatalities included 84 truck drivers, 21 security services workers, 13 law enforcement officers, nine utility workers, seven building grounds maintenance workers and five firefighters. The impact of high-visibility apparel standards is by no means unique to the United States. The European market has been transformed by personal protection equipment legislation since early 1990s, where all motorists risk a fine if they do not wear a reflective garment while carrying out emergency operations outside their vehicles. ANSI/ISEA 207-2006 Vests that meet this standard give users enhanced visibility in all lighting conditions, through the combined use of fluorescent and retro-reflective materials, says ISEA Technical Director Janice Comer Bradley. The new standard includes basic requirements such as vest dimensions, color, and performance of materials, and incorporates specifications for special features for users in fire, emergency medical and law enforcement services including the need for color identification of individual service entities. ANSI/ISEA 207-2006 also addresses the specific requirements of law enforcement professionals, such as the need to access a gun or other belt-mounted equipment and the ability for the vest to tear away from the body.

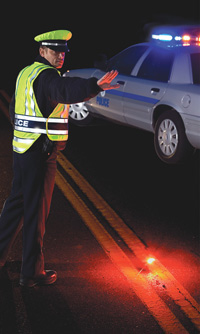

APPAREL ITEMS Fechheimer These industry leaders combined resources to develop high-visibility safety products that meet the new ANSI/ISEA 207-2006 standards. The vest was specifically designed to ensure the overall safety of public safety professionals who work at night and/or in low-visibility conditions. Head Lites Corp. is the first manufacturer to comply with the new ANSI 207 standard to provide the Pro Series Tactical Safety Vest to all public safety industries. Products featuring 3M Scotchlite reflective material use technology known as retroreflection to create greater visibility in dark or low-light conditions. Retroreflection occurs when reflected light rays are returned directly to the original light source, causing that material to appear brightest to an observer located near the light source. The Pro Series Tactical Safety Vest is designed with strategic placement of horizontal and vertical 3M Scotchlite bands on a fluorescent background to ensure the wearer has 360-degree maximum visibility at night and in other low-light conditions. This ultra-effective combination of a fluorescent background and 3M Scotchlite reflective material provides public safety professionals with a higher level of confidence in their visibility and safety. Special Safety Features: In addition to the special safety features built into the Pro Series Tactical Safety Vest, there are standard value-added features offered that benefit the wearer. Features:

Snap N Wear Plus, not only does each shell fabric have an inner urethane coating, but all the seams in the apparel are taped. These jackets are ultra waterproof. The taping prevents water from passing though the shell by sealing all the small holes created by the needle when the garments are assembled. Features: Also Available:

Safety Flag Company The vests are particularly popular among police departments and security personnel because of their extremely high visibility compared to standard fluorescent and reflective vests. Like other Safety Flag mission-critical apparel and equipment, these ANSI Class 2 vests are made with retroreflective 3M Scotchlite high-gloss reflective material. Because of the materials prismatic cell design and differentiated orientation, the vests are visible from many directions when light strikes from an angle. The vests are available in both fluorescent green and fluorescent orange, with three options for striping: reflective silver, fluorescent/reflective lime-yellow, and fluorescent/reflective red-orange. ANSI Class 2 is only one of three classes of ANSI-approved vests offered by Safety Flag. All meet new ANSI/ISEA 207-2006 standards. I believe the Safety Flag ANSI Class 2 vests are popular because they make officers safer and for reasons of cost and customization, Bernson notes. The vests are all made in the United States, reducing shipping costs and making them cost-effective, and they are easily customized by Safety Flag, he says. Customization includes size, cut, color, pockets and legends identifying city, town, department or company. Common legends might be NYC or Centerville PD or EMS, as well as standards like POLICE or SECURITY. Vests are available in mesh as well as solid fabric. They can be cut to allow easy access to duty gear and are secured with hook-and-loop fasteners for easy and quick removal. Other ANSI Class 2 vest designs, with five-point breakaway fasteners and fire-retardant treatment, are available. Features (Also applicable to Safety Flags ANSI Class 1 and Class 3 vests):

Bulwark LiteFX also provides protection from the suns harmful rays. The product lineup includes high-quality, ANSI/ISEA 107-2004 compliant and enhanced-visibility shirts, jackets and vests. Features:

COMPONENTS Metlon The company has decades of experience designing and building special purpose machinery for its own use to meet specific customer requirements. They serve a wide variety of industries which need slitting either because they have no slitting facilities or have a need to supplement their capabilities. Metlon takes pride in being a leader in the custom slitting and converting industry. Since being named a One Star Authorized Distributor of 3M Scotchlite reflective material, Metlon has seen the uniform side of its business greatly expand. The relationship has really helped us grow our uniform business, and its an area where we see enormous possibilities, says Wayne Etchells, Metlons executive vice president. Current end uses for Retroglo include public safety professionals, airline technicians and highway workers. Because of its aesthetic appeal, the yarn is also popular in sports and active wear and is used by labels such as DKNY, L.L. Bean and Eddie Bauer. Metlon also sees the lucrative childrens wear market as a potential opportunity. Many of the products have been third-party tested and certified in accordance with ANSI/ISEA retroreflective material specifications. Available in These Components:

3M Company With a growing interest in taking high-visibility safety apparel beyond the vest to primary apparel, such as work wear and outerwear, an offering in this category is essential, says Cory Erickson, market development manager in 3Ms Visibility and Insulation Solutions department. The improved drape and moisture vapor transmission of these segmented trims provides improvement in the comfort for apparel used in the occupational markets we serve. The unique design of the segmented trim provides improved wicking performance so workers can stay dryer and cooler, while the increased flexibility makes garments more comfortable for all movement. Both the 5510 Segmented Home Wash Trim and the 5530 Segmented Industrial Wash Trim are designed for improved wash durability, which can contribute to a longer garment life. Both meet retroreflective performance standards and are certified to ANSI, Canadian Standards Association and other standards. The segmented trims are being produced and marketed through a business relationship between 3M and Safe Reflections Inc. Working with 3M will broaden customized applications of Scotchlite reflective material to meet a unique and growing need in the marketplace, says Bob Koppes, owner of Safe Reflections. We are very excited to be expanding our relationship with them to better serve the occupational industry. Both components of the Scotchlite reflective material are expected on the market in mid-2007 through a variety of garment manufacturers.

|

|

|

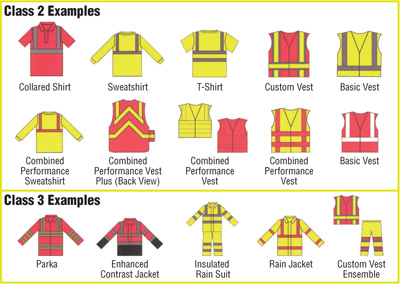

SELECTION GUIDE To provide guidance for the protection of all those exposed to the hazards of limited visibility, the ANSI approved ANSI/ISEA 107-2004, the American National Standard for High-Visibility Safety Apparel. ANSI/ISEA 107-2004 establishes design, material, photometric and physical performance requirements, care labeling, and marking rules for high-visibility garments. The following guide may help when selecting garments with the proper type, class and design placement for each work environment. ANSI/ISEA 107-2004 Classes: Class 1 Garments: Class 2 Garments: Class 3 Garments: ANSI/ISEA 107-2004 Garment Examples

|

|

| Above story first appeared in MADE TO MEASURE Magazine, Fall & Winter 2007 issue. All rights reserved. Photos appear by special permission. | |

| Halper Publishing Company 633 Skokie Blvd, #490 Northbrook, IL 60062 (877) 415-3300 Fax (224) 406-8850 [email protected] |

|

Home Fall & Winter 2007 High Visibility Market Expected To Shine Brightly Feds Put November 2008 Deadline...